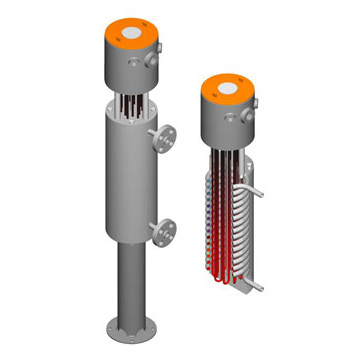

Electric process heater type CEH

Certificates

Product inquiry

ATEX / IECEx

In general a cooling down takes place at expansion of gases whilst a heating takes place at compression. Typical gases are carbon dioxide, domestic gas and air. The temperature change, which occurs at expansion of gas or gas mixture from a high to low pressure i.e. after a gas pressure control is called Joule-Thomson effect. In order to prevent the effects of Joule-Thomson as icing or condensate separation, the gas will be heated up before expansion. The gas pre heaters are suitable for all kind of gaseous media (i.e. air, natural gas, technical gases, fuel gas) and low flow process applications, suitable for pressures up to 300 bar.

The “Cast electric heaters” type flameproof electrical gas pre heaters are certified for use in zone 1 or 2 hazardous area, custom built to meet client specification. The gas pre heater consists of a process tube coil and an electrical heating bundle, casted in aluminium. The process gas flows through the tube coil and is heated by the aluminium block that provides the heat transfer. This indirect electric heating gives an accurate control of the process and eliminates pressure vessel design and associated costs.

The electrical enclosure contains a process gas temperature controller and a temperature limiter. The sensors of these thermostats are mounted in the aluminium block by means of protective pipes.

Thyristor control systems and flameproof control systems are also designed and manufactured to control the range of electric process heaters. We are pleased to advice on the most suitable control system for your heating application.

Deutsch

Deutsch